A Successful L-Plate Solution for the GFX 100S

This L-plate from Rogeti (pictures below), a new player in the camera L-plate market appealed to me with a couple of aspects of its design — the diagonal brace for stiffening of the vertical arm of the one-piece plate (my preference to a full-wide, two-part plate design) and the inclusion of a trio of tubular levels for:

1) Roll of the camera in horizontal position

2) Roll of the camera in vertical position

3) Pitch of the camera in either position

The first two I expect to be useful at times and the other would be for people doing architecture or 360 panoramic captures.

The plate was described as neither in stock nor backordered on the website. I nevertheless placed my order from California on the Chinese website on Sunday July 4th, 2021, for $129 plus California sales tax, via PayPal. The shipping was free, and as it turned out, was from a fulfillment company in Mountain View, California.

I received the plate today, Monday July 19th, a shorter turnaround time than has been typical so far for getting plates for this camera from at least two of the other three companies that have announced such products: SmallRig, Kirk and Really Right Stuff. After making a few dozen snapshots of it, I checked out how it seems to fit the camera. When it’s gently pressed against the camera, it can twist, as expected, because only the front edge of the base of the L-plate is raised, curving up around the curved, lower front edge of the camera. The back edge of the plate is not also raised, e.g., as the Kirk plate is for the GFX 100S. This was actually another feature of the Rogeti plate which I figured might be a plus, assuming that the plate would not be prone to twisting on the camera after being installed.

That’s because the raised feature (a little wall about 2 mm tall and about 3 inches wide) on the Kirk plate actually interferes in two ways with the camera’s LCD. I’m hoping Jeff Kirk will alter the little wall of his design (by making it about about 20 mm shorter on the right side) so as to always allow the L-plate to avoid touching it. The bigger of two problems occurs when the LCD is tilted back, as for when holding the camera over your head. The right side of the lower edge of the LCD hits the little wall when you simply tilt the top edge of the LCD out most of the way, which feels like it could damage the LCD's hinging support.

My sense of the Rogeti’s twisting behavior is that you just press the plate in from the end and back across the front, with the screw almost snug, taking up the left-right slack and the twisting slack, tighten the big, slotted screw (using the supplied magnetic “coin” that lives in the base of the L-plate) and the plate snugs up convincingly. It’s not my impression that the screw will necessarily come loose over time, but I may prove to be inclined to watch it to make sure the camera is never endangered. I suppose of it starts to come loose I’ll notice it easily enough before the camera could fall. So, it seems fine.

As for the slightly crude Rogeti machining that I’ve seen in a close-up photograph online, that’s not what I got. The machined surfaces are quite fine, and finished with a texture that is suggestive of bead blasting perhaps. It feels good and looks precise.

Next thing: Are the levels accurate? In order to check a level accurately, one must make a reading then reverse the level and split the difference, being sure it’s in the same position on the very flat surface, because no level is perfectly accurate (that I’ve ever seen). So I used my 2.5” long Starrett pocket level, flipping it end for end many times as it rested on the L-plate's appropriate surfaces, to make sure that the L-plate was precisely leveled in all three dimensions, one at a time, on my desk. I shimmed the plate as needed to get it super level. For one of the three setups it turned out that the best shim was an 8-micron steel shim from a feeler gauge. The 10 was too thick. No kidding. For the others it was a piece of paper or a sterilizing pad packet edge.

In all three cases, when the plate was truly level, the bubble was to the right of center (easier to remember at least, where true level is when all three are about the same). The snapshots below show all three levels’ readings (bubble positions) as seen from almost perfectly straight on, with the L-plate perfectly leveled.

Here is the level for for assessing roll angle when the camera is horizontal, as seen from behind the plate:

And here is the level for assessing roll angle when the camera is vertical:

Finally here is the level for assessing the pitch angle. This level is for use with the camera in either orientation, but this level accuracy check only applies when the camera is in horizontal orientation ("landscape"):

So the levels could be a tad more accurate but they're pretty good. They’ll be easy enough to use so as to outperform an in-camera, LCD-displayed artificial horizon tool when hand-holding and I can see the roll levels better than the tubular level for roll adjustment at the back of my Gitzo 3-way fluid head. Not bad.

Also: Some have complained about how the Rogeti felt in their hands, because of the relatively square corners in the lower left. My initial impression was that this wasn’t an issue, but after holding the camera for off-tripod work for a couple of hours it does become a problem, despite the hand grip being at the other end. If you hold the camera with your left hand, your palm will be up and the corners poke your palm in a way that's uncomfortable and makes little temporary marks all over it. To avoid that, you're limited to left-hand holding, where you're gripping by the base of the lens, either palm up and facing back or facing forward. When actually making pictures, instead of spending many hours trying to figure out Fujifilm's seriously complex menus, I'm expecting this to not be an issue for me, but if one works hand-held, it may also be troublesome. Fuji's neck strap is a nice one and will certainly help when I'm doing any hand-held work, which the IBIS system makes eminently possible. I do like the Rogeti design work overall, but this issue, caused in part by the accommodation of the pitch and vertical orientation roll tubular levels, is a tradeoff. Rogeti could round off these end corners just a bit more I think.

[Later, Feb 2, 2022: I took a tiny, fine file and carefully radiused the offending sharp corners, with the L-plate off the camera so as to ensure that none of the invisibly tiny aluminum filings could contaminate the camera. I radiused all six of the corners at the lower left corner of the L-plate and now it feels considerably better in the left hand. Note that it became obvious that Rogeti's pretty, gray coating of the machined aluminum part is not hard anodizing, else the tool steel of the tiny file would have barely been able to touch it.]

I had also been substantially concerned about the way the floor of the GFX 100S pressed down against the top of the Kirk plate. The plate is flat on top as expected, but the camera is not flat on the bottom. With the Kirk, I was able to measure a gap as large as just over 9 mils (0.009”) between the top of the plate and the bottom of the camera just forward of the tripod screw location, with the two in firm contact. I could also shine light under the plate and see it plainly on the other side, and measure with a feeler gauge (meaning in this case a cut scrap of laser paper) where the plate and camera touched and get a sense for how the surfaces interact, with the rear and front edges of the camera's bottom touching, but much of the central region ahead of the tripod screw hole not touching. Examining the base of the camera suggested it might tend to create a gap as big as 4 mils on account of the camera's own irregularities in shape, so I can't account for all of what I saw.

I've read that someone doing a teardown of the camera concluded that the inner frame strength of the camera at its base is not what it should be, so I’ve been wanting to know that the fit of the camera to the plate that winds up living on it would not aggravate the base of the camera, which could mean the screw pulls the base down causing it to bow, for example, or perhaps that force on the camera transferred to the tripod would injure the camera more readily with some plate designs than others. I don’t know that the Kirk plate could have been any better in this respect, but I was thinking when I had it that I might want to shim the top of the plate with a fine quality, 2-mil 3M industrial polyester and acrylic adhesive tape to partially fill the air gap between a portion of the L-plate and the base of the camera, the gap being the camera's fault most likely. I couldn't see how the Kirk plate might be itself contributing to the rather substantial thickness of this air gap.

With this Rogeti plate I can’t see as much of what’s going on between the plate and the camera, space/air gap wise, simply because of its design, so at this point I’m thinking I’ll just accept the fit and not worry about it even though it probably doesn't actually fit any closer all over to the base of the camera than the other plate did. It certainly feels good to the touch, but that can’t tell the full story.

All in all, I like this new plate. The vertical arm seems clearly rigid enough. The Kirk may have had extra anti-twist support, beyond that coming from the way the base of the plate fits the bottom of the camera, nestled across both the front and the back edges, from the camera’s strap lug fitting snugly into a slot at the top of the vertical arm of the plate, but I couldn’t see that slot well enough to tell how snugly the strap lug fit into it, thanks to the triangular strap anchor being in the way, whether, for example it might actually be touching either or both walls of the slot, but I’d be surprised if it touched both, to be sure. In any case, the Kirk plate felt quite secure and solid on the camera. I think that if they tweak the little ridge across the back of the plate’s top surface it will be a winner in every respect. It goes for $150 plus shipping, the price difference not being a consideration in my choice.

My long wait for a usable L-plate for my new camera is finally over, four months after receiving the camera. Even now, the Really Right Stuff plate is still backordered but the Kirk and SmallRig plates for this popular camera are in stock. All things considered, I’m happy with this part. I would prefer to see more of what we all buy being made here, but the equipment still needs to meet my own requirements. I do hope for the best for Kirk. It's good for everyone if RRS has sturdy competition. A bunch more snaps and a few more comments below. One more thing: I don't use quick-release clamps so I can't tell you whether this plate now accords with the RRS standard dimensions for that use.

—Joseph Holmes

I'm hoping the most important level can't get hit while the camera is being put into an arca-swiss clamp. The end of this level is recessed only about 1 mil from the end of the metal there. OK, I just tried connecting it to the RRS panning clamp that I use atop my tripod head and the level is kept safely away from the metal of that clamp at least. I see that the plate seems to change color at times, looking blacker in this picture that it really looks. On the other hand, this plate does look substantially darker than the one shown on their website, which I think is an improvement. A nice, dignified, silvery, dark gray. But notice how it seems to be a light silver color in the fourth picture down. Maybe it's just a matter of how they lit the thing for their product pictures.

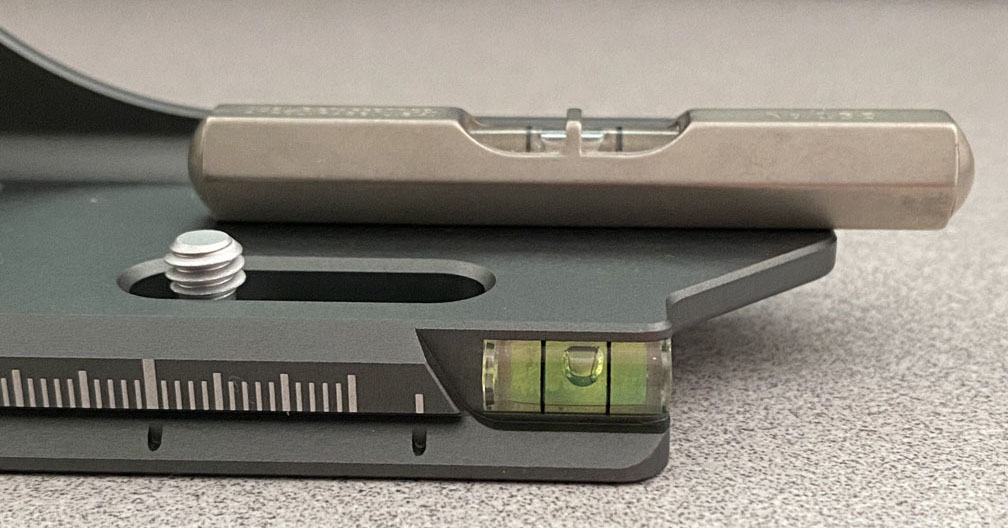

Two of the three levels:

This one gives a good idea of the texture used all over. That's the plated steel "coin" that's magnetically held to the bottom of the plate. It's less than 1mm larger in diameter than a quarter (U.S. 25 cent coin) and all of one mil thicker. I'd say that a quarter would do in a pinch but the edges of the Rogeti coin are a bit better fit to the slot in the screw.

Notice the three concave, curved surfaces on the plate. The one across the lower front edge of the camera and the one that runs up the left front corner of the camera both seem to hug the camera nicely, but the one at the left edge of the bottom of the camera doesn't fit snugly, doesn't actually touch, just comes very close. It all feels totally solid on the camera. Actually the vertical curve only touches along its back edge I see, the part of the curve closest to the back of the camera. I'm not sure exactly where the curve across the front touches the camera.

It makes more sense to me to keep my camera strap connected to the camera directly than to use the one provided at the top of the vertical arm. The groove at the base of the vertical arm looks like it may serve nicely for cables.

This shows the smallest gap possible between the vertical arm and the strap lug. The lower 60% or so of the forward part of the vertical arm curves around and is pressed against the rubber coating more to the side of the camera than the front, adding firmness to that provided by the structure of the L, with its innovative diagonal brace across the front of the camera. Even though the rear side of the vertical arm is away from the side of the camera by 0.24" (~6.1mm) they couldn't bring it in any closer without precluding the opening of the two rubber doors unless you loosened the screw and extended the bracket out to the side. It moves out 0.80", judging by the two indicated screw positions on the bottom of the L-plate. It is required that the plate either be all the way in or all the way out, as there are two corresponding recesses for the screw head machined into the plate.

Two rubber doors open — note that the top one hits a bit while being opened and requires a little push from the side with something narrower than a finger to get it opened up. This suggests they got the distance of the vertical arm to the side of the camera exactly right.

Bottom view with rubber doors open:

And another side view with the two rubber doors closed again:

Circled in white is the small gap between the LCD and the L-plate at the closest they get: